Products and Processes

Here’s a brief list of the products we manufacture

- Glareshield (with or without upholstery)

- Headliner assy (air valve, lights, harness)

- Ventilation ducting system (twin sheets)

- Handle (polyurethane)

- Machining of non-metallic parts

- Interior panel (thermoforming or composite)

- Center console

- Fuel cell block (polyurethane)

- Arm rest (composite or polyurethane)

- Many other parts

Processes

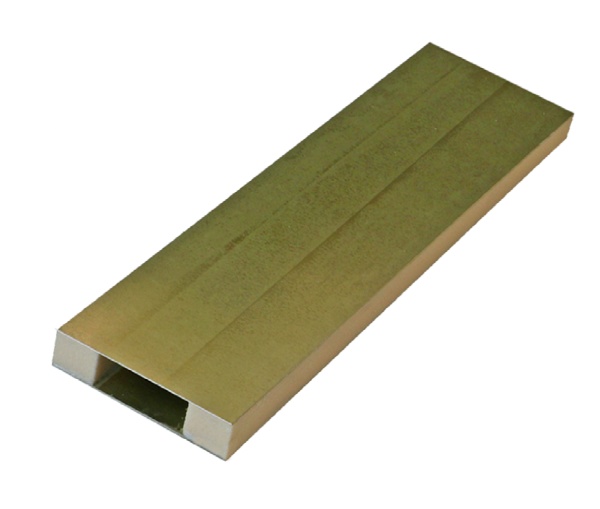

Thermoforming

It can also be used to produce twin sheet forming parts, such as ventilation ducts.

Interior panel, ventilation ducting system, headliner assembly, etc.

Processes

- Vacuum molding

- Twin sheet forming

Materials

- ABS

- ABS/PVC

- Acrylic/PVC

- Polycarbonates

- Polyetherimide

- Polyethylene and others

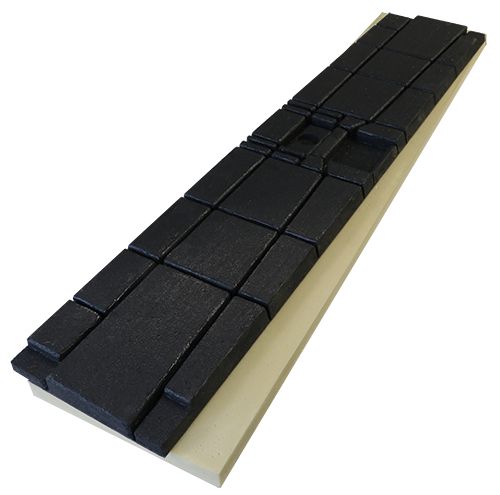

Non-metallic machining

Machining of non-metallic materials using CNC machines

Processes

- 5 axis

- 3 axis (milling)

- Router

- Lathe

Materials

- Foam

- Ultem

- Nylon

- Teflon

- Phenolic

- Acrylic

- Kydex

- Polycarbonate

- Delrin

Composite

Lightweight, high-strength parts. Parts can be simple laminates or laminates with a core.

Glareshield, pedestal, center console, side console, interior panel, arm rest, etc.

Processes

- VARTM

- Rolling in a clean room

Materials

- Phenolic resin/Glass fiber

- Epoxy resin/glass fiber

- Epoxy resin/carbon fiber

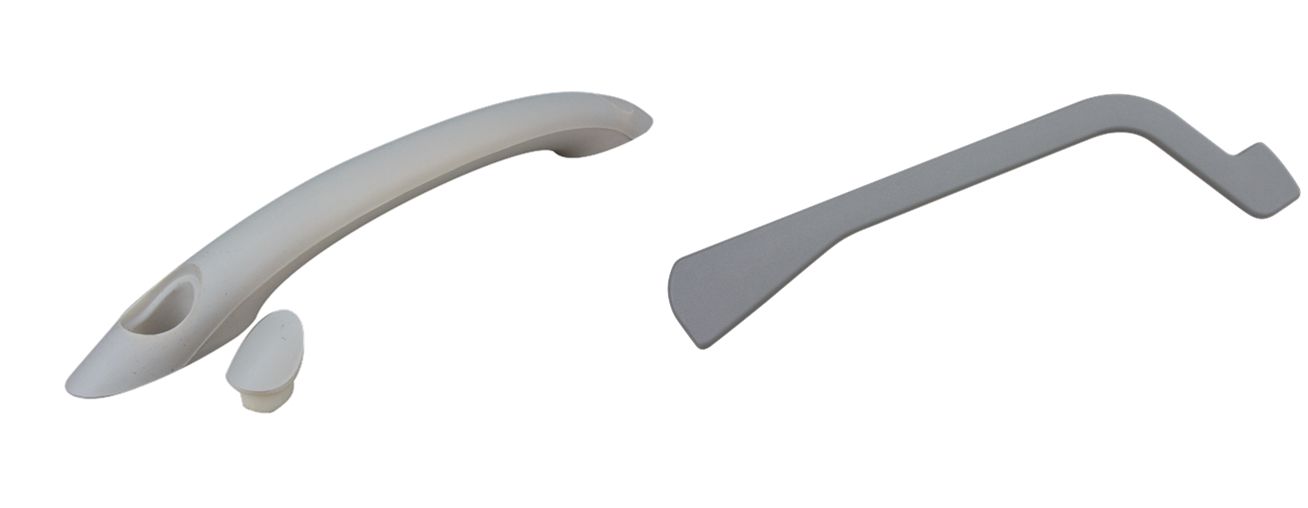

Polyurethane

Suitable for molding flexible parts (headrests, armrests, etc.) or rigid parts (fuel cell blocks). Offers a wide range of customization options (color, texture, hardness).

Handle, head bumper, footrest, fuel cell blocks, etc.

Processes

- Cast / Expanded

Materials

- Rigid polyurethane

- Flexible polyurethane

Drape forming

This process is well suited to acrylic forming.

Processes

Materials

- Acrylic

- Polypropylene